HARARE – Zimplats Holdings has reported a 21% increase in total operating costs to US$162.851 million in the third quarter to September 30, from US$134.981 million in the same period last year, driven by higher labour costs, increased expenditure on equipment maintenance, and expanded smelter operations.

According to the company’s third-quarter report ended September 30, operating costs rose by 18% from the prior quarter, largely due to salary adjustments, mill relines at two concentrator plants, and planned replacements of conveyor belts. The prior quarter’s costs were positively impacted by power credits accrued from the solar plant, which was commissioned in August 2024.

The cash cost of metal produced increased by 27% year-on-year to US$1,068 from the same period last year of US$841 and 30% quarter-on-quarter, as lower production volumes and higher operating costs took their toll. Notably, a concentrate inventory accumulation during smelter repairs resulted in a US$10.7 million transfer from operating costs to stocks.

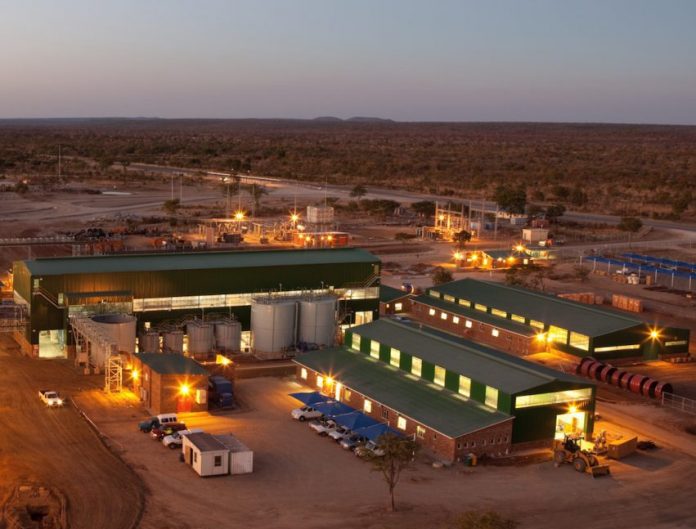

The increased costs come as Zimplats continues to invest in its operations, including the expansion of its smelter and the construction of a solar power plant. The company’s commitment to growth and sustainability is evident in its ongoing capital projects, aimed at increasing production capacity and reducing environmental impact.

During the period under review, the company made significant progress on its major capital projects, positioning Zimplats for future growth. The Mupani Mine development, which will replace the depleted Rukodzi and Ngwarati mines, remains on schedule to reach full production capacity of 3.6 million tonnes per annum by FY2029, with $352 million spent to date against a total budget of $386 million.

The smelter expansion and SO2 abatement plant project is also advancing, with $461 million spent out of a total budget of $544 million. Additionally, the company has commenced implementation of the Phase 2A 45MW solar plant, expected to be completed in H1 FY2027 for $54 million, and has spent $12 million with a further $36 million committed.

Other projects include the Selous Metallurgical Complex Concentrator tailings storage facility extension and the Base Metal Refinery refurbishment, with $4 million and $35 million spent respectively.

Meanwhile, mined volumes experienced a marginal 1% decrease from the prior quarter, while remaining stable year-on-year. Specifically, open-pit mining volumes were slightly lower than the previous quarter due to pit design adjustments, whereas underground mining volumes remained consistent quarter-on-quarter. Notably, mined volumes from pillar reclamation at Rukodzi Mine were offset by production from lower-grade ore at South Pit.

The 6E head grade declined by 2% compared to the prior comparable period and 1% from the prior quarter. This decrease was attributed to the depletion of high-grade ore from Rukodzi Mine and the processing of lower-grade ore at South Pit. Despite stable milled volumes, concentrator recoveries were negatively impacted by the lower head grade and inconsistent ore supply. As a result, concentrator recoveries declined by 4% and 2% from the prior quarter and previous comparable period, respectively.

The decline in concentrator recoveries and lower head grade resulted in a 6% and 4% decrease in 6E concentrate production compared to the prior quarter and previous comparable period, respectively. Final metal production was further impacted by extended repairs to the furnace slag tap hole, resulting in a 24% decrease from the prior quarter and a 5% decline from the previous comparable period.

Consequently, 6E metal in the final product stood at 142,535 ounces. Approximately 12,600 ounces of 6E concentrate inventory accumulated during the period will be smelted in the remainder of the financial year.